Testing potential improvements can get complicated when you're working with multiple suppliers in different steps of a process, but conducting experiments in Minitab Statistical Software to determine significant inputs and then importing your model into a Minitab Workspace Monte Carlo Simulation can help shed some light on the results you'd see. Plus, it's faster and cheaper than running more tests on real parts.

Consider the case of Spaceman Electronics (as with all our use cases, this is based on real-life situations we have seen in the field, but Spaceman is a fictional company). To make a part for one of their products, one supplier makes the core and another coats it. Then it comes to them to assemble the finished product.

In the past Neil, a product engineer at Spaceman, has instructed the production line managers to implement a scrap factor of 7% to account for some units not fitting well enough into the product. A scrap factor is a percentage of the batch that you can anticipate will be destroyed or ruined during manufacturing or processing operations (for instance if you are making 100 units and have 7% scrap historically and 93% of the batch is good, you would divide 100 by 0.93 and round up, determining that you need to make 108 units).

If Neil's team can reduce that scrap rate, which costs them $0.70 per unit, they can see cost savings upwards of $165,000 every year. It could be cumbersome and time-consuming to try to make improvements if they don't make their directions for both of their suppliers as precise as possible, though. So he sets out to simulate some potential results in order to make a well-informed decision before telling the suppliers what to change in their processes.

How Monte Carlo Simulation Works

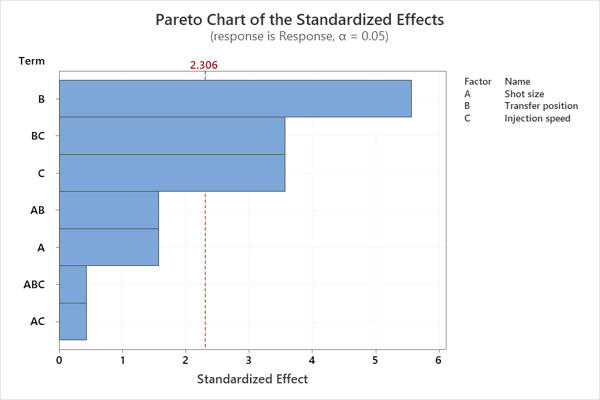

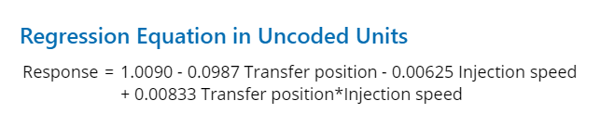

Monte Carlo Simulation uses a mathematical model of the system and the simulation provides expected values based on an equation defining the relationship between the inputs and outputs. Neil and his team planned and conducted a series of experiments in Minitab to determine significant factors in the process. They generate a Pareto Chart showing that transfer position and injection speed are the factors they want to focus on, and the equation they are going to use in Minitab Workspace:

Importing Your Model and Running It in Minitab Workspace

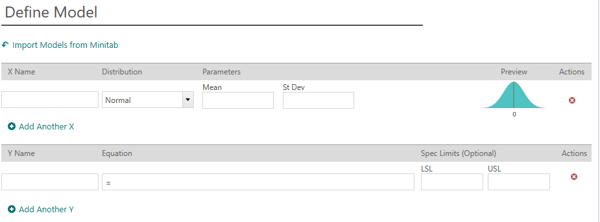

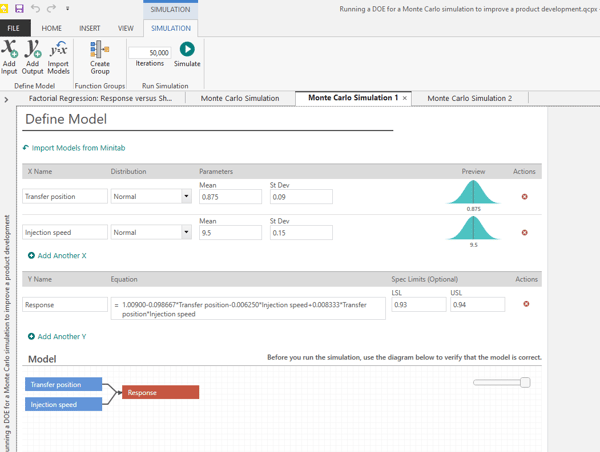

Now that they have that equation, Neil opens up a project in Minitab Workspace and inserts the Monte Carlo Simulation tool. He could manually enter his inputs and outputs and type in an equation through the options for this tool available in both Minitab Workspace and Minitab Engage (more on that in this example), but they already have that information so he can jump ahead a bit.

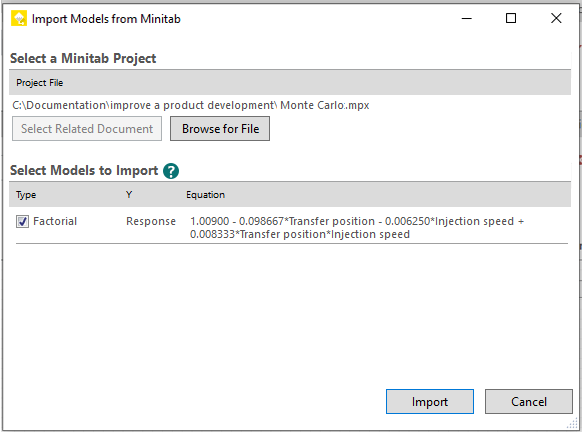

Neil clicks the option for importing the model from Minitab and chooses his Minitab file.

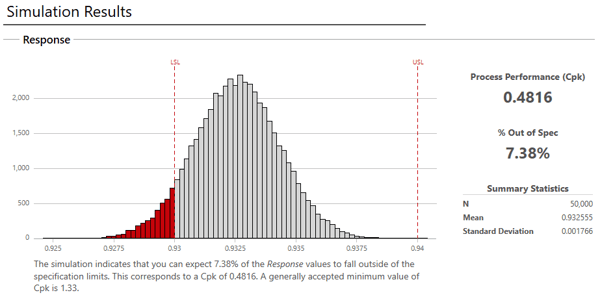

The equation automatically pulls in transfer position and injection speed as X inputs. He knows these factors have a normal distribution, so he selects Normal from the dropdown menu and then enters the means and standard deviations as well as the upper and lower specification limits. Then he hits the green Simulate button near the top and Minitab Workspace completes 50,000 simulations for the process within just a couple seconds:

Understanding the Results and Parameter Optimization

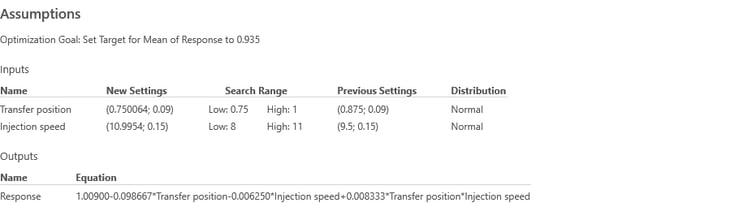

The process performance measurement (Cpk) for this process is 0.4816, far short of the minimum standard of 1.33. Below this visualization, a green button, "Parameter Optimization," appears guiding Neil to the next step: optimizing his inputs. He sets the goal (targeting for the mean of the response to be 0.935, halfway in between his upper and lower specification limit) and enters high and low values for his inputs to explore, and then Minitab Workspace does the rest. He hits "Optimize Parameters" and sees this.

The process performance measurement (Cpk) for this process is 0.4816, far short of the minimum standard of 1.33. Below this visualization, a green button, "Parameter Optimization," appears guiding Neil to the next step: optimizing his inputs. He sets the goal (targeting for the mean of the response to be 0.935, halfway in between his upper and lower specification limit) and enters high and low values for his inputs to explore, and then Minitab Workspace does the rest. He hits "Optimize Parameters" and sees this.

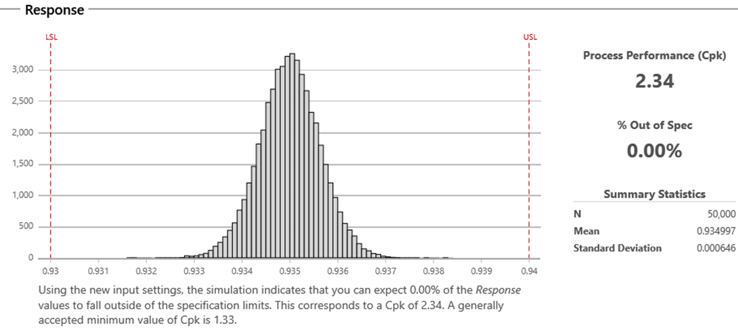

After finding the optimal input settings in the ranges Neil specifies, Minitab Workspace presents the simulated results for the recommended process changes. The simulation indicates that the optimal settings will virtually eliminate out-of-spec product from the process, with a Cpk of 2.34 — a vast improvement that exceeds the 1.33 Cpk standard.

Getting Great Results

When Neil shares his findings, the suppliers can optimize the geometric dimensioning and tolerance of the part, not just reducing the amount of scrapped product but also shortening the manufacturing cycle time.

Try Both Minitab Statistical Software and Minitab Workspace for Free!

Thanks to Minitab Solutions Architect Antonio Vargas for the research and technical support on this use case!