To celebrate Minitab’s support of the recent International Conference on Teaching Statistics in Kyoto, Japan, we sat down with Dr Rozzeta Dolah, whose career and work in statistics and engineering has taken her to her native Malaysia, to Japan and then the USA where she is currently working as a Post-Doctoral Fellow at MIT in Cambridge, Massachusetts.

In the first part of our talk to Dr Dolah, she tells us about her education and what sparked her interest in quality engineering.

Tell us about your educational background. I completed my undergraduate degree in chemical technology at Universiti Kebangsaan Malaysia in 2002. I did my Master’s Degree in Mechanical Engineering (Advanced Manufacturing Technology) at Universiti Teknologi Malaysia (UTM) while I was working as a process engineer at ShinEtsu Handotai: SEH (M) Sdn. Bhd., a semiconductor manufacturer.

At UTM with Professor Datuk Ir. Dr. Wahid Omar

I then did my Ph.D in Mechanical Engineering at Meiji University, Tokyo. My area of focus was the development of robust quality engineering for measurement systems, using peel strength measurements as my case study for evaluating the Taguchi Method. When I returned to Malaysia, I continued working at Universiti Teknologi Malaysia (UTM) as a senior lecturer in Razak Faculty of Technology and Informatics and in 2016, I was offered a post-doctoral position by the Massachusetts Institute of Technology (MIT). Last year, I continued my work in the MIT Department of Mechanical Engineering and am now in the Microfluidics and Nanofluidics Research Laboratory with Professor Rohit Karnik. My research interest involves renewable energy in biomass conversion into biofuels and nanotechnology using robust quality engineering including Taguchi method optimization.

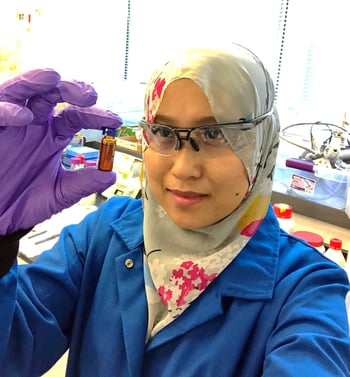

At the MIT Mechanical Eng. Department’s Microfluidics and Nanofluidics Research Laboratory

At the MIT Mechanical Eng. Department’s Microfluidics and Nanofluidics Research Laboratory

How did you get into teaching? After six years working in the industry, I became a lecturer at UTM under Razak Faculty of Technology and Informatics. I really felt that having the industry background and working as an academic is such a privilege; I had hands-on experience and understood the industry better when I taught students, in addition to having the networking and relationships with former employees. Working in the manufacturing industry has created an interesting academia-industry collaboration.

What inspired you to pursue a career in this field? My love of science and engineering started when I was at school. I love science, including biology, chemistry, and physics. I feel that with science and engineering, we can make things better in life and discover ways to survive. We are makers. We learned from civilization that science and engineering are the main pillars for national development, and that these that are part of the vehicles to human development. From a patriotic point of view, we need science and engineering for the development of a country.

Let’s go back to your studies in Japan – what were you able to learn there to implement in your teachings at UTM and MIT?

My experience in Japan was so precious. The people and the culture are so special, sometimes in contrast to the very modern and advanced technologies they have. I benefited from the Look East Policy that was introduced in the early 1980’s which challenged Malaysians in the economic and industrial sectors to learn from Japan and South Korea. I wrote an article for The Star about this policy and the impact it has had on my career.

My passion for quality engineering came from my experience in industry when aiming for zero defects with minimal costs and time wastage, and I learned we must identify suitable tools for problem solving to optimize a process. I attended a Black Belt Six Sigma course in SEH (M) Sdn. Bhd. and was impressed that wafer defects were reduced to almost zero with increased production yield.

So I focused on this for my Ph.D and was fortunate to gain direct guidance from the son of the late Dr. Genichi Taguchi, Engr. Shin Taguchi, a pioneer in one of the Six Sigma tools known as the Taguchi Method, as well as from my main supervisor, Prof. Zenichi Miyagi in the Measurement Information Laboratory and my co-supervisor, Prof. Bo Bergman from Chalmers University of Technology, Sweden. My Ph.D analyzed the differentiation between the Taguchi Method and Design of Experiments (DOE), about how they differ, and when, and where to use it.

In Japan, there is an annual Taguchi conference called the Quality Engineering Society (QES) conference. The audience comes from industry and academia, and they discuss how they solve problems and improve the production process and products using the Taguchi Method. Some well-known brands attend, including Toyota, Nissan, Honda, GE, Konica, Minolta, FujiXerox, and the presenters range from engineers, technicians, managers, CEOs, and professors. I met Prof. Noriaki Kano at QES, who invented the Kano Model, a theory for product development and customer satisfaction developed in the 1980s.

Dr Dolah with Engr. Shin Taguchi, the son of the late Dr. Genichi Taguchi, the pioneer of Taguchi Method

Dr Dolah with Engr. Shin Taguchi, the son of the late Dr. Genichi Taguchi, the pioneer of Taguchi Method

In Japan, I found that the industry sought help from academics to solve their problems. I was taught that one’s contribution to society is important and found that the Japanese are so helpful to each other and are very civic-minded. I believe this is something that we need to follow to have this kind of academia-industry relationship. Malaysia is similar in that we see many companies linking with universities for their innovations and process improvements, but the hardest part is to sustain it and make it work! The theory is ensured to be practical to the practitioners. However, the language used in this conference is Japanese and sharing this knowledge outside Japan is rather difficult. From here, I got the idea on how to disseminate the Taguchi method outside Japan.

Prof. Sha’ri M. Yusof, Dr. Khairur Rijal and I, all from UTM, initiated the first QES conference in English called the International Conference on Robust Quality Engineering (ICRQE) in 2013. As for now, we have run the conference four times, alternating host countries including India and Indonesia. We also started a Taguchi Centre situated in Razak Faculty of Technology and Informatics, Kuala Lumpur making it one of the quality engineering hubs in South East Asia. Its full name, the Genichi Taguchi Centre for Quality and Sustainability(田口センター), formally launched on 4 August 2018 during 4th ICRQE held in UTM KL recently. It is the first Taguchi Centre in South East Asia, and the ICRQE has been the first Taguchi Conference conducted in English. The Taguchi Centre was approved by Engr. Shin Taguchi, and his mother, Mdm Kiyo Taguchi. So you can see, Japan has had a major impact on my career!