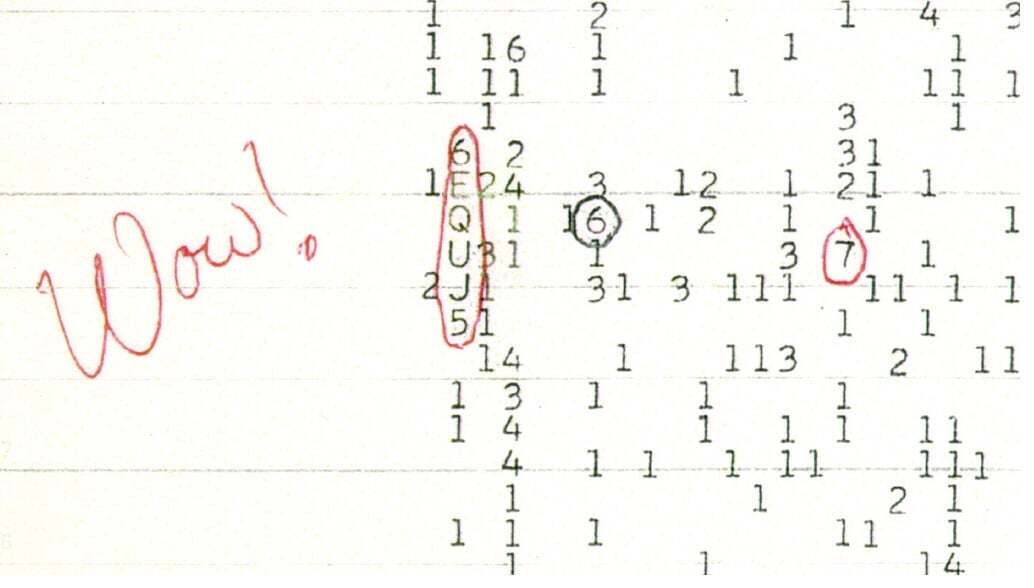

Poring over a printout of radio signals in the late 1970s, an astronomer at the Big Ear telescope at Ohio State University was flabbergasted to discover what appeared to be a big ole “How-Do-You-Do?” from space aliens, jumping out from the everyday mish-mash of earthly radio signals. He circled the signal and recorded his amazement in the margin in red:

The signal appeared to come from the constellation Sagittarius and lasted 72 seconds. At the time, it generated keen excitement among those searching for intelligent life in the universe and came to be known as the “Wow!” signal.

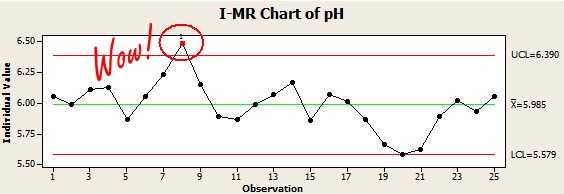

Does the signal remind you of anything? Here’s a hint:

Detecting a “signal” amidst “everyday noise” is what happens when you use a control chart to monitor statistical process control (SPC). You’re trying to distinguish between natural, everyday variation in your process due to common causes from unexpected, “alien” variation that’s due to special causes (the Wow! signal).

Why do you want to do that? It’s not like it’s going to give you the chance to meet your potential soulmate from the Andromeda Galaxy.

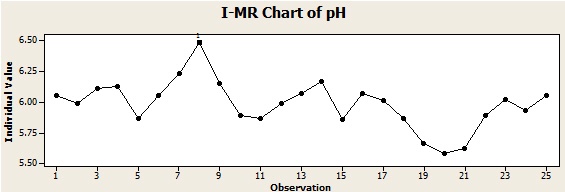

To understand why the distinction between common causes and special causes is important, look at the same chart without control limits or special signals for out-of-control points:

Although the chart still shows you the general pattern of variability (it’s just a time series plot now), every marked increase or decrease looks a potential suspect for a “Wow! signal.” Using this chart alone, you’ll have a tough time figuring out which specific process changes to investigate as potentially “out-of-the ordinary.”

A special cause typically calls for an immediate investigation and response to correct the problem. But if you take action to “correct” every common cause as if it were a special cause, you’ll waste a lot of time, money, and energy. What’s worse, you’ll risk making your process subject to even greater variability and unpredictability. This is called “tampering”— whereby too many adjustments over-correct the variability of a process and actually make it more unstable.

That would be like the astronomer interpreting every radio signal from Earth as if it were sent by Jar Jar Binks, the Yip Yips, or the Great Gazoo. Ultimately, it could make your quality team overreact to natural, common variation in your process like this:

To avoid taking your quality team and your process on a wild and crazy goose chase, you might want to wait until you hear Minitab exclaim “Wow!”

What’s Next: Are you curious about the original Wow! signal discovered in the 1970s? Did astronomers ever figure out what it meant? We’ll took at that in an upcoming blog…stay tuned.