Effective quality management demands real-time insights and proactive interventions. Minitab Real-Time SPC makes quality analysis and improvement easy in one convenient solution, providing Quality professionals with a comprehensive tool to save both time and money. Let's explore the top 5 ways Minitab Real-Time SPC can help improve quality:

1. Continuous Monitoring for Early Detection

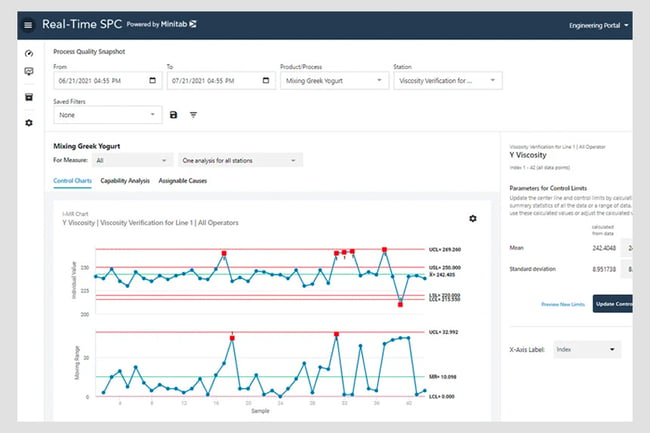

Real-Time SPC allows for continuous monitoring of key quality indicators. Imagine a manufacturing line where the thickness of a critical component is monitored in real-time. With Real-Time SPC, any deviation from the desired specifications triggers immediate alerts, enabling swift corrective actions before defects accumulate.

Real-Time SPC helps waste areas like scrap, rework, and under-performing machinery, which ultimately improves ROI.

Real-Time SPC helps waste areas like scrap, rework, and under-performing machinery, which ultimately improves ROI.

2. Reducing Variability for Consistent Quality

By analyzing real-time data, Quality professionals can identify and reduce process variability. Consider a pharmaceutical production setting where Real-Time SPC is applied to monitor the temperature during drug formulation. Maintaining a consistent temperature ensures uniform product quality, reducing the likelihood of variations in the final product.

3. Enhancing Process Stability

Real-Time SPC provides the tools to enhance process stability. In an automotive assembly line, real-time monitoring of torque specifications ensures that each bolt is tightened consistently. Any deviation is flagged immediately, preventing potential assembly issues and ensuring the stability of the production process.

4. Improving Overall Equipment Effectiveness (OEE)

Real-Time SPC contributes to maximizing OEE by minimizing downtime and optimizing equipment performance. For a food processing plant, real-time monitoring of critical parameters such as temperature and pressure ensures that equipment operates within specified limits. This minimizes unplanned downtime and contributes to overall efficiency.

Read our one-pager to learn 3 Common Quality Problems That Can Be Solved Using Minitab Real-Time SPC

5. Enabling Predictive Quality Analytics

Real-Time SPC goes beyond reactive measures by enabling predictive analytics. In a semiconductor manufacturing environment, real-time analysis of equipment performance indicators can predict potential issues before they affect product quality. Proactive maintenance can then be scheduled, preventing quality deviations.

Watch our Webinar: Next-Generation SPC for Manufacturing: Reduce Scrap, Predict Defects, and Maximize Profits

Minitab Real-Time SPC is not just a tool; it's a strategic approach to quality assurance. By providing real-time insights, reducing variability, enhancing stability, optimizing equipment, and enabling predictive analytics, Real-Time SPC becomes the cornerstone of a future where quality is not just maintained but continually elevated.

Ready to elevate your quality management? Explore Minitab Real-Time SPC and embrace a future where excellence is not a goal but a constant journey.