In quality initiatives such as Six Sigma, practitioners often need to assess the capability of a process to make sure it can meet specifications, or to verify that it produces good parts. While many Minitab users are familiar with the capability analysis tools in the Stat menu and in Minitab’s Assistant, the Assistant includes a less-frequently used feature—the Capability Snapshot.

What Is the Capability Snapshot, and When Is It Useful?

The Shapshot can give you a capability estimate when data have not been collected over a long enough period of time to validate process stability (a key assumption for a true process capability analysis) or to capture the different sources of process variation.

The Capability Snapshot provides the most information possible from the limited data provided.

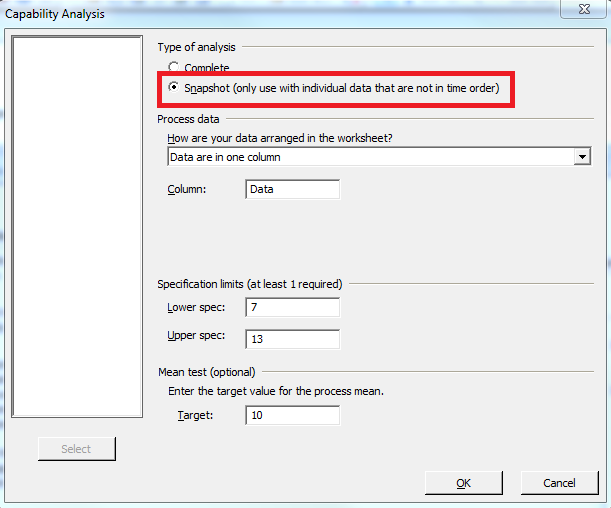

The Assistant's Snapshot mentions using this option only with data that are not in time order, but remember that even if the measurements being used are stored in the worksheet in the order in which they were collected, data collected over a short period of time won't capture the true long-term variation in the process. The time order here refers to data that has been collected over a long period of time, not data that is merely sequential.

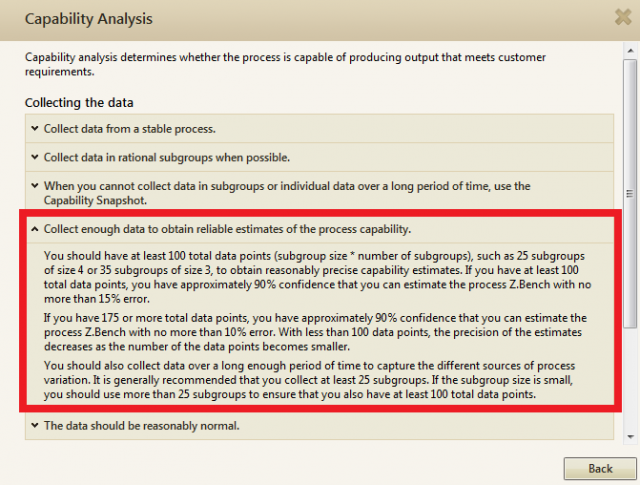

According to the guidelines set forth in the Assistant’s Capability Analysis menu for a standard Capability Analysis, sufficient data must be collected over a long-enough period of time to obtain reliable estimates of process capability:

In some situations, it may not be possible to collect enough data over a sufficiently long period of time to obtain precise estimates or capture the different sources of variation.

For example, parts produced in an R&D laboratory are not likely produced in the same environment—by the same operators, using the same equipment, at the same temperature, or more generally under the same operating conditions—as they would be in a manufacturing plant making parts for customers. Similarly, it may not be possible to produce enough parts in an R&D laboratory. In some situations only a few parts can be produced and it may be necessary to estimate the capability of the process based on this limited information.

Capability Snapshot to the Rescue!

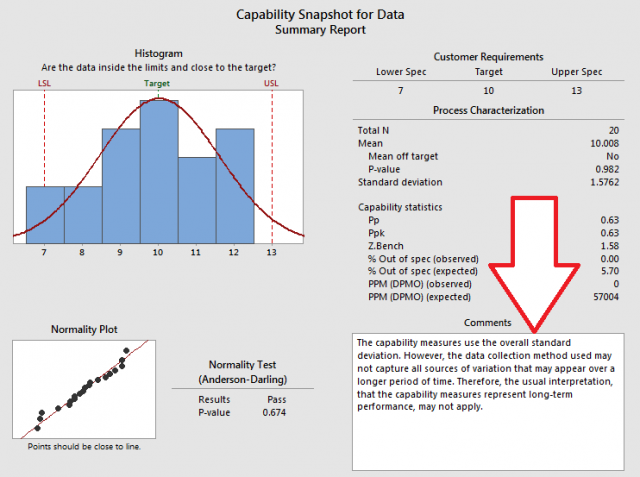

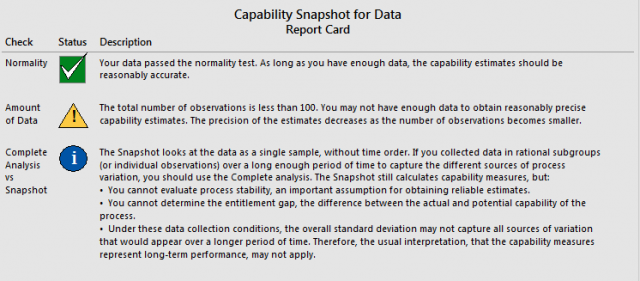

If you choose the Capability Snapshot, Minitab only estimates the overall standard deviation. Because the analysis makes no assumption about the amount of time over which you collected the data, it is not possible to determine whether the variation in the data represents the inherent variation (typically captured by within-subgroup variation) or the overall variation of the process (which can only be estimated over the long-term).

In other words no subgroups are assumed, and only the overall variation in the sample is used.

Because the calculations use the overall standard deviation of the sample, the resulting output is labeled Ppk…. However that number should be interpreted with caution! The overall standard deviation for a snapshot of the process may not capture all sources of process variation that would be observed if the data were collected over the long-term. Because of that, the Ppk in this output cannot be interpreted in the usual way.

So Do the Capability Snapshot Statistics Represent Cpk or Ppk?

As one of Minitab’s fantastic (and hilariously entertaining) trainers, Paul Sheehy, likes to say, “No mother, no father—it’s neither!” Some like to argue that it represents Cpk, or within-subgroup variation. But to truly capture within-subgroup variation, we calculate the variation averaged across many subgroups of data, and in this case, we only have one ‘subgroup.’

Others prefer to think of the resulting capability estimate as Ppk, or overall variation. And even though that is how the output is labeled in the Capability Snapshot, the data that is typically used for this type of analysis does not capture the variation from the process over the long term, so it's not quite the same metric as traditional Ppk.

If that seems like a lot to remember, don't worry about it! The output from the Assistant is packed full of guidance and helpful tips to guide your interpretation of the results:

To read more about Capability Analysis, check out Eric Heckman’s blog post (which you’ll really like if you’re a Star Wars fan!): Starting Out with Capability Analysis.