Adam Russell is a Global Operations Master Black Belt, Tate & Lyle.

Adam Russell is a Global Operations Master Black Belt, Tate & Lyle.

Tate & Lyle deploys Continuous Improvement (CI) tools, including Minitab and Salford Predictive Modeler (SPM), to address challenging engineering and manufacturing problems. Our company operates large-scale, continuous flow processes serving the Food & Beverage industry.

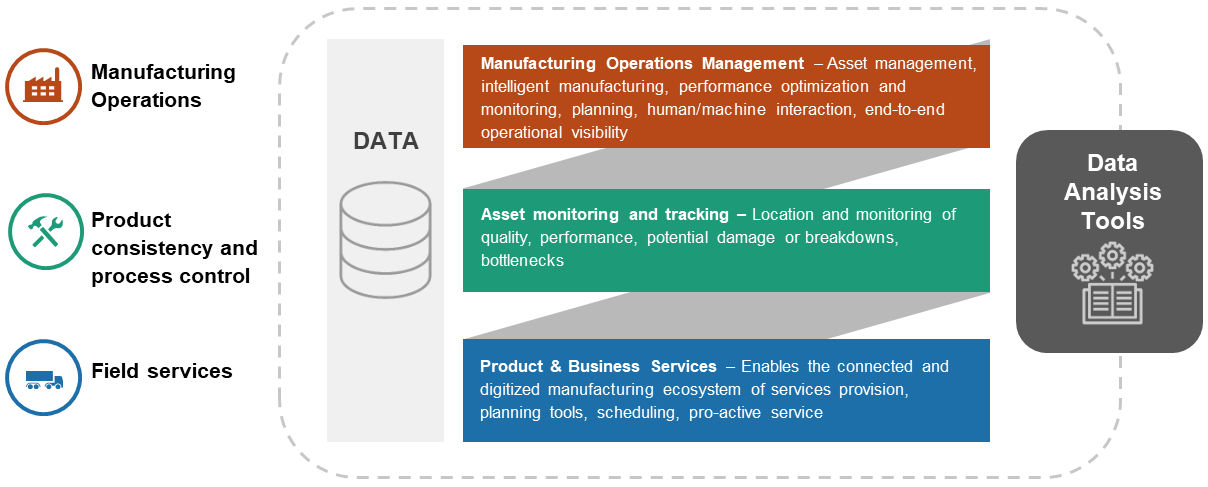

Product consistency and process control are often complicated by a combination of chemical, microbiological, and physical influences. Time-series analysis of the data is also required to properly understand and control cause-and-effect relationships.

By resisting the urge to over-emphasize tribal knowledge and “this is how we’ve always done it” thinking, CI teams at Tate & Lyle are using the DMAIC methodology and modern data analysis tools to understand complex patterns that exist within historical data. This strategy has allowed these teams to tackle problematic issues that have existed for a long time in some cases, drive to deeper understanding of root causes, and progress through improvement projects.

Minitab graphic

While we see no limit to the types of problems that can be addressed, the tools have been immediately helpful addressing customer quality, yield, and operational performance problems.

Minitab graphic

Data analysis is hard work in a company like ours where endless amounts of information are generated continually from our manufacturing processes. SPM and Minitab provide us with reliable, user-friendly tools to efficiently screen thousands of predictors and have greater confidence that actions we take will produce the desired results.