Last week I was fielding questions on social media about the latest version of our statistical software. Almost as soon as the new release was announced, we received a question that comes up often from people in pharmaceutical and medical device companies:

"Is Minitab FDA-validated?"How Software Gets Validated

That's a great question. To satisfy U.S. Food and Drug Administration (FDA) regulatory requirements, many firms—including those in the pharmaceutical and medical device industries—must validate their data analysis software. That can be a big hassle, so to make this process easier, Minitab offers a Validation Kit.

We conduct extremely rigorous and extensive internal testing of Minitab Statistical Software to assure the numerical accuracy and reliability of all statistical output. Details on our software testing procedures can be found in the validation kit. The kit also includes an automated macro script to generate various statistical and graphical analyses on your machine. You can then compare your results to the provided output file that we have validated internally to ensure that the results on your machine match the validated results.

Intended Use

FDA regulations state that the purchaser must validate software used in production or as part of a quality system for the “intended use” of the software. FDA’s Code of Federal Regulations Title 21 Part 820.70(i) lays it out:

“When computers or automated data processing systems are used as part of production or the quality system, the manufacturer shall validate computer software for its intended use according to an established protocol.”

FDA provides additional guidance for medical device makers in Section 6.3 of “Validation of Automated Process Equipment and Quality System Software” in the Principles of Software Validation; Final Guidance for Industry and FDA Staff, January 11, 2002.

“The device manufacturer is responsible for ensuring that the product development methodologies used by the off-the-shelf (OTS) software developer are appropriate and sufficient for the device manufacturer's intended use of that OTS software. For OTS software and equipment, the device manufacturer may or may not have access to the vendor's software validation documentation. If the vendor can provide information about their system requirements, software requirements, validation process, and the results of their validation, the medical device manufacturer can use that information as a beginning point for their required validation documentation.”

Validation for intended use consists of mapping the software requirements to test cases, where each requirement is traced to a test case. Test cases can contain:

- A test case description. For example, Validate capability analysis for Non-Normal Data.

- Steps for execution. For example, go to Stat > Quality Tools > Capability Analysis > Nonnormal and enter the column to be evaluated and select the appropriate distribution.

- Test results (with screen shots).

- Test pass/fail determination.

- Tester signature and date.

An Example

There is good reason for the “intended use” guidance when it comes to validation. Here is an example:

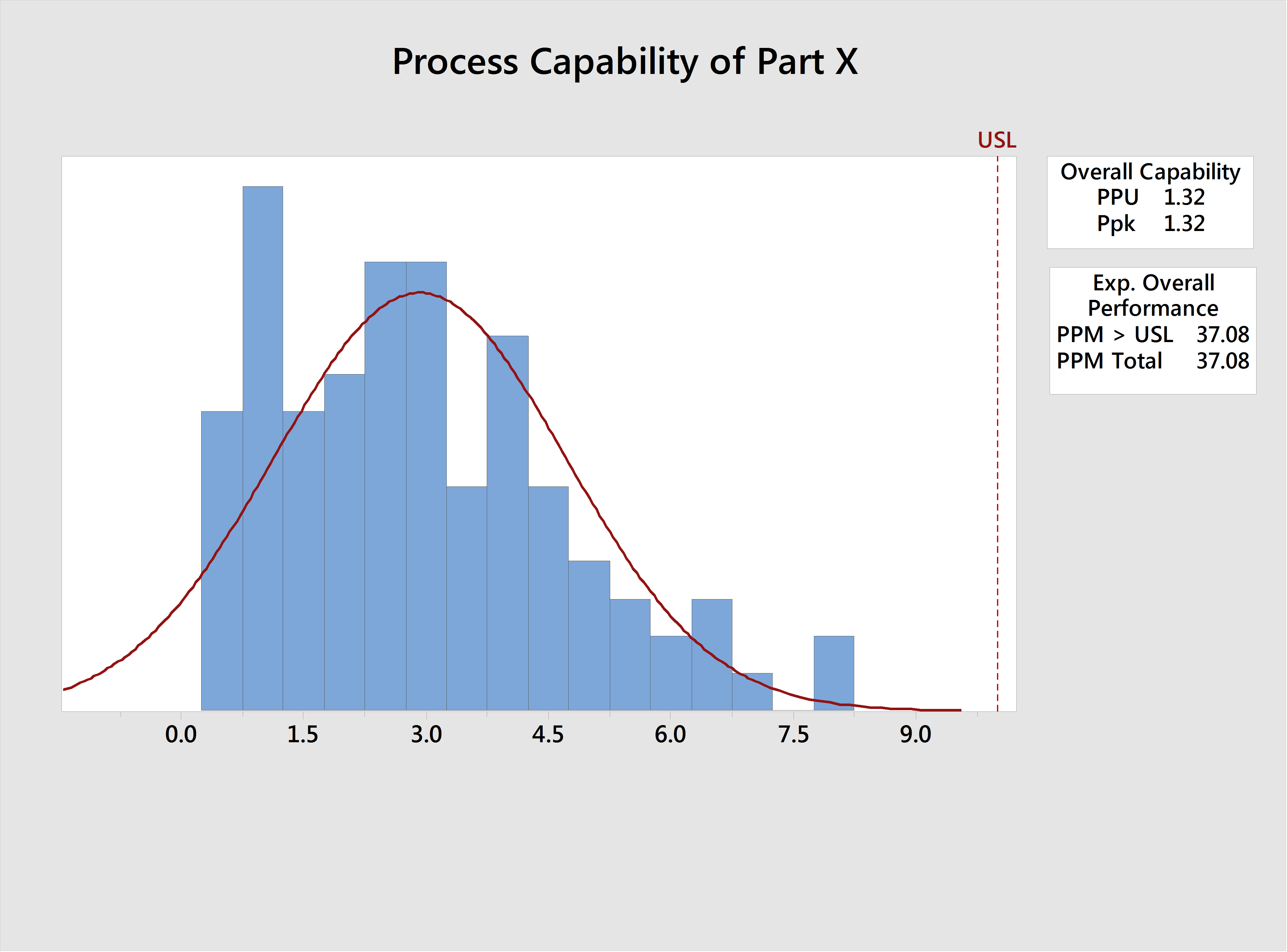

Company XYZ is using Minitab to estimate the probability of a defective part in a manufacturing process. If the size of Part X exceeds 10, the product is considered defective. They use Minitab to perform a capability analysis by selecting Stat > Quality Tools > Capability Analysis > Normal.

In the following graph, the Ppk (1.32) and PPM (37 defects per million) are satisfactory.

However, these good numbers would mislead the manufacturer into believing this is a good process. Minitab's calculations are correct, but this data is non-normal, so normal capability analysis was the wrong procedure to use.

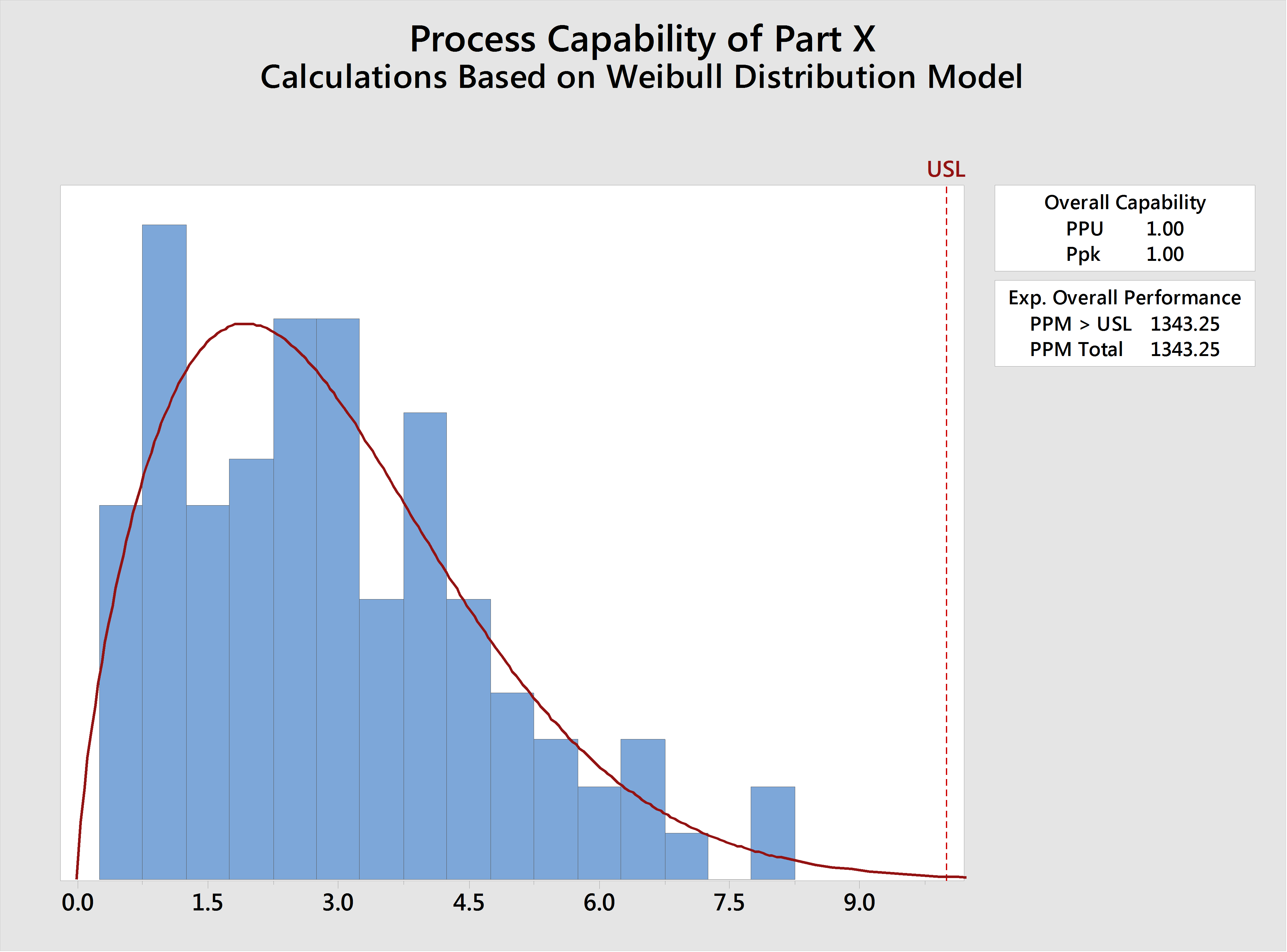

Fortunately, Minitab also offers non-normal capability analysis. As shown in the next graph, if we choose Stat > Quality Tools > Capability Analysis > Nonnormal and select an appropriate distribution (in this case, Weibull), we find that the Ppk (1.0) and PPM (1343 defects per million) are actually not acceptable:

Thoroughly identifying, documenting, and validating all intended uses of the software helps protect both businesses that make FDA-regulated products and the people who ultimately use them.

Software Validation Resources from Minitab

To download Minitab's software validation kit, visit http://www.minitab.com/support/software-validation/

In addition to details regarding our testing procedures and a macro script for comparing your results to our validated results, the kit also includes software lifecycle information.

If you have any questions about our software validation process, please check out our training options or contact us.