The ultimate goal of most quality improvement projects is clear: reducing the number of defects, improving a response, or making a change that benefits your customers.

We often want to jump right in and start gathering and analyzing data so we can solve the problems. Checking your measurement systems first, with methods like attribute agreement analysis or Gage R&R, may seem like a needless waste of time.

But the truth is that a Gage R&R Study is a critical step in any statistical analysis involving continuous data. That's because it allows you to determine if your measurement system for that data is adequate or not. If your measurement system isn’t capable of producing reliable measurements, then any analysis you conduct with those measurements is likely meaningless.

So let’s get to the “R&R” part of Gage R&R—Repeatability and Reproducibility.

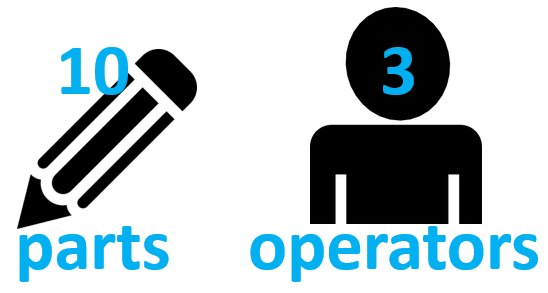

Suppose we’re measuring pencils with a ruler (which is an excellent hands-on activity you can use to teach Gage R&R). We want to determine if our measurement system can adequately measure the length of these pencils. To conduct a Gage R&R Study, we randomly select 10 pencils and 3 people—Abe, Brenda, and Charlie. Each person measures each pencil 2 times, using the same ruler. This gives us a total of 10 x 3 x 2 = 60 measurements.

Repeatability

Repeatability represents the variation observed when the same operator measures the same part multiple times with the same device. In other words, when Abe repeatedly measures the same pencil with the same ruler, will his measurements be consistent? If he measures 16.8 cm the first time, is he going to measure 16.8 cm the next time he measures that same pencil?

Reproducibility

Reproducibility represents the variation observed when DIFFERENT operators measure the same part multiple times with the same device. In other words, if Abe measures a pencil at 16.8 cm in length, will Brenda also measure 16.8 cm for that same pencil? And what about Charlie?

Helpful Hint: To remember the difference between repeatability and reproducibility, note that reproducibility includes an ‘o’ – think ‘o’ for the variability across “operators.”

Answering Important Questions

Gage R&R can help you answer questions such as:

- Is my measurement system capable of discriminating between parts?

- Is the variability in my measurement system small compared with the manufacturing process variability?

- How much variability is my measurement system is caused by differences between operators?

And if your measurement system isn't great, you can also use Gage R&R to determine where the weaknesses are. For example, perhaps a study reveals that while repeatability is good, the reproducibility is poor. You can use Gage R&R to dig deeper and figure out why different operators reported different readings.

To easily setup your Gage R&R data collection plan and analyze the corresponding data to assess your measurement system, check out Minitab Statistical Software and its Stat > Quality Tools > Gage Study and Assistant > Measurement Systems Analysis features.