With the steady rise in energy costs, some organizations feel pressured to proactively develop strategies to reduce their energy consumption.

According to Reuters, energy efficiency measures remain essential to further support decarbonization efforts and reduce energy use, especially in energy-intensive industries, such as iron and steel, cement, and petrochemicals.1 The article also states that by having a detailed view of energy consumption and developing strategies to reduce it, companies can invest in cost-effective measures that often have a significant payback.

How Can Organizations Successfully Conserve Energy?

With a good action plan powered by data-driven decisions, businesses can uncover valuable saving opportunities to reduce their carbon footprint. In this blog post, we cover three main strategies to help you reach efficient energy conservation and Minitab solutions that help you achieve sustainability success. Let’s begin with our first strategy.

Strategy 1: Manufacture Using Partially Recycled Materials

Signify2, the world leader in lighting technologies, is committed to contributing to a more sustainable future by driving development of eco-friendly solutions. This includes manufacturing products that can be reprinted or refurbished, and services dedicated to reusing materials for conservation efforts.

For example, lamp recycling benefits human infrastructure by reducing power usage for resource extraction. This also has an environmental impact by decreasing resource scarcity. Through specialized treatment facilities, over 80% of lamp recyclables are reusable, providing numerous economic opportunities while furthering ecological protection practices worldwide.

Real-Life Use Case

To maintain their sustainability efforts, Signify began using partially recycled materials for 3D printing of lighting materials. Their goal was to provide printed products to their customers as quickly as possible while using recycled materials and conserving energy.

By using House of Quality available in Minitab Engage, along with data analytics Minitab Statistical Software, Signify was able to tailor their lighting materials to not only meet the needs of the customer, but also release faster products designed for the Circular Economy, and increase energy efficiency. In addition, Signify reduced their failure rate and saved a significant amount of non-classified costs per year.

Next, we’ll highlight ways to manage energy waste.

Strategy 2: Maintain Equipment to Eliminate Energy Waste

One of the possible causes for energy waste is improper equipment maintenance. Motors may run hot due to alignment issues or damaged bearings, for example.

To reduce energy consumption, organizations can do any of the following:

- Regularly inspect their plant’s equipment and devices

- Determine the most efficient approach for maintenance, upgrades, and replacements

- Place equipment in low-energy mode during certain hours

In addition to an equipment plan, having an effective preventative maintenance approach is essential to maximize cost savings over time. Predictive maintenance techniques can help to anticipate the need for equipment maintenance.

Knowledge around material degradation, along with data about the processes and equipment, will give your team valuable information about the reliability of your equipment. Reliability of an item is the probability that it will adequately perform its specified purpose, for a specified period of time, under specified environmental conditions. Luckily, Minitab Statistical Software has the reliability tests to determine the lifetime and risk of failures of parts, products, and equipment.

Real-Life Use Case

A commercial aircraft manufacturer wanted to reduce downtime for a specific jet engine flex hose. By using Minitab Statistical Software, they wanted to predict its reliability by scheduling part replacements within 282 days.

After running the analysis, the manufacturer determined that flex hoses will last at least 282.4 days. Scheduled replacement before that timeframe reduces unscheduled maintenance and downtime, resulting in large cost savings for the manufacturer.

By leveraging data already gathered from their analysis, teams can confidently predict product lifetime and reliability through advanced graphical and quantitative analysis techniques. By doing this, they will feel more secure in understanding potential mechanical failures before they even occur. These insights will help them evaluate the risks of energy inefficiency associated with designs or objectives and forecast outcomes for optimization purposes - all while working quickly and efficiently.

Lastly, we’ll cover our third energy consumption strategy.

Strategy 3: Routinely Monitor Your Processes & Materials

Another way to optimize energy efficiency is to monitor your plant’s processes and materials on a regular basis. This allows for improvement across teams to pinpoint root causes and streamline problem-solving throughout their organization.

Real-Life Use Case

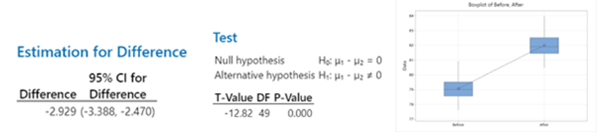

One of the world’s largest solar technology and renewable energy companies needed to control the thickness of the silicon nitride film, after it discovered inconsistencies in their manufacturing process.

-Jul-05-2025-11-51-15-5369-PM.png?width=548&height=194&name=MicrosoftTeams-image%20(46)-Jul-05-2025-11-51-15-5369-PM.png)

Using the powerful charting and analysis tools available in Minitab® Statistical Software and Minitab Engage™, the company was able to pinpoint and rectify the causes of differences in film thickness.

With Minitab’s powerful analytics and improvement solutions, the manufacturer was able to improve energy efficiency of their panels by 7% and increase their annual revenue by more than $100,000 per year.

Before you apply changes to your manufacturing process, the quality of the released products needs to remain consistent. Minitab has the solutions to ensure that the quality of your products meets the customer expectations and is compliant with regulatory standards.

Other examples to consider:

- If you’re looking to make tradeoff analysis between investment costs and energy efficiency, Graph Builder in Minitab Statistical Software would be a great solution.

- DMAIC projects available in Minitab Engage can be used to track improvements, while Monte Carlo can be used to simulate proposed changes for your initiative.

Conclusion

These are just a few of many strategies that your organization can implement to achieve energy conservation success. Insights from your data can help you to decide the most appropriate strategies for your business, and Minitab is your end-to-end analytics and CI solution toward energy efficiency.

Are you ready to put the power (and cost) back in your hands to achieve better energy efficiency? Watch our on-demand webinar to explore how optimized processes can increase efficiency, enhance equipment and material usage, and lower costs.

Sources:

1. Reuters "EU Reaches Deal on National CO2 Emission Cut Targets"

2. Signify Webinar "Break habits, not your products: How Signify switched materials and processing without sacrificing reliability"