It's that time of year again for holiday bakers and cookie monsters to unite over lots of delicious treats (and we definitely deserve them after this very long year)!

So what’s a baker with quality on their mind to do when their favorite sugar cookie recipe made cookies that failed to hold their festive holiday shape after being baked? Run a Design of Experiment (DOE), of course!

Start with a Fractional Factorial Experiment

Maud Ward, an avid baker and graphic designer at Minitab, used Design of Experiment (DOE) tools in Minitab Statistical Software to get to the bottom of her sugar cookie shape faux pas.

Maud, with the help of Minitab's fabulous technical support team, designed an experiment that would allow her to screen many factors, determine which were most important, then adjust her process to get the results she wanted—in this case, to make cookies that held their shape after being baked.

She decided to run a fractional factorial experiment, a class of factorial designs that lets you identify the most important factors in a process quickly and inexpensively.

Maud’s experiment required her to make eight runs (or batches of cookies) to assess six factors, each of which was tested at two levels:

-

- Oven temperature: 325°F or 375°F

- Number of eggs: 1 or 2

- All-purpose flour: 9 oz. or 13.5 oz.

- Baking soda: 0.5 or 1 tsp

- Cream of tartar: 0.5 or 1 tsp

- Chill dough after rolling and cutting: Yes or No

To ensure consistent dough thickness, Maud used wooden strips to prevent her rolling pin from flattening dough any thinner than ¼ inch (6.35mm). She then randomized the placement of the cookies on the baking sheet to minimize undue influence or unintentional bias during the baking process and rotated the baking sheets 180° halfway through baking.

Because two oven temperatures were used in the experiment, baking times varied by trial. The actual cooking times for each trial were recorded on the trial instruction sheet.

Each trial consisted of baking two trays of cookies. When they came out of the oven, Maud measured two samples of each shape from both trays to see if there had been a change in overall height, a selected width measurement, or thickness. These dimensions were recorded on preprinted forms, which identified the trial number, data of trial, width and height. Maud calculated averages and standard deviations for her cookie shape, then used Minitab Statistical Software to analyze the data.

Getting Delicious DOE Results

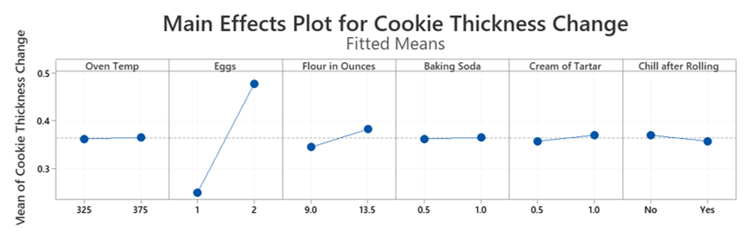

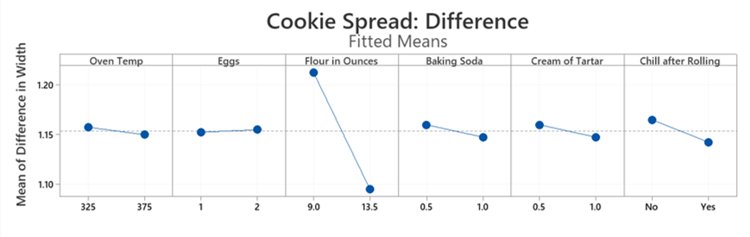

An analysis of height and width measurements done in Minitab revealed that flour was the driving factor in spread of the cookie. “In each instance, a higher amount of flour produced less spreading from the original dimension,” Maud said. “Impact on cookie thickness was mainly influenced by flour and the number of eggs in the batter. Using two eggs produced more rise than with just one.”

Maud then used Minitab to create main effects plots, which examine the differences among level means for one or more factors.

Lastly, the response optimizer helped identify the factor settings that resulted in minimal spread and maximum height.

| Variable | Oven Temp. | Eggs | Flour | Baking Soda | Cream of Tartar | Chill after Rolling |

| Setting | 375°F | 2 | 13.5 oz. | 1 tsp | 1 tsp | Yes |

Maud is now confident the experiment she designed and analyzed thanks to Minitab and the technical support team will result in better cookies this holiday season and for many more holidays to come. Sounds like perfectly, tasty results to me!

Have you ever used DOE to optimize a recipe?