I got the chance recently to learn about how the United States Army used Minitab Statistical Software to improve a crucial internal process for deciding a soldier’s job status following a medical concern.

This decision is made through the MOS/Medical Retention Board Process (MMRB) and affects nearly 8,000 soldiers and their families per year, as well as numerous military commanders in charge of staffing.

The Army was taking an average of 61 days to reach decisions, and some outlier cases took as long as 400 days. The long lead time for this assessment kept soldiers’ careers in limbo, because they cannot deploy, make a permanent change of station, or go to school until a determination is made.

An Army Lean Six Sigma team set out to reduce the long lead times these soldiers face. They sought to decrease the average process cycle time from 61 to 45 days, while also standardizing and centralizing the process to remove variability.

How Minitab Helped

The Army Lean Six Sigma team used the DMAIC approach to frame their project. The team developed process maps to fully understand the current state of the MMRB process and identified possible root causes. After the team defined process bottlenecks and collected baseline data, they turned to Minitab for further analysis to investigate the factors that were impacting the process.

The team used Minitab’s Analysis of Variance (ANOVA) tools to both uncover new factors that were negatively affecting the process and to statistically verify that the factors the team had identified were causing increases in cycle time. With Minitab, the project team could clearly tell that defects in MMRB documentation, as well as variations in process guidelines across different units within the Army, were contributing to the long cycle times.

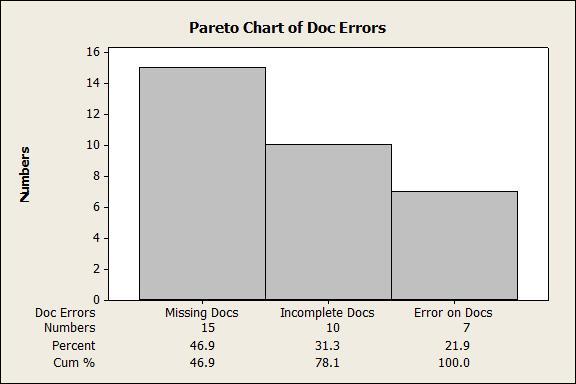

They used Minitab to create a Pareto Chart of documentation errors for the MMRB process, which helped them to quickly identify and prioritize critical documentation errors. They were able to pinpoint missing documentation as a key concern, and then made improvements to specifically address this process weakness.

Minitab’s Multi-Vari Charts also aided the team by presenting ANOVA data graphically, revealing relationships between various factors and how they affected cycle time.

The project team brainstormed and identified possible solutions for process problems, then mapped out a new centralized process and performed pilot testing to ensure the new process reduced cycle time. After a few more tweaks to their new process, which the team renamed MOS Administrative Retention Review, or MAR2, they collected additional pilot-test data.

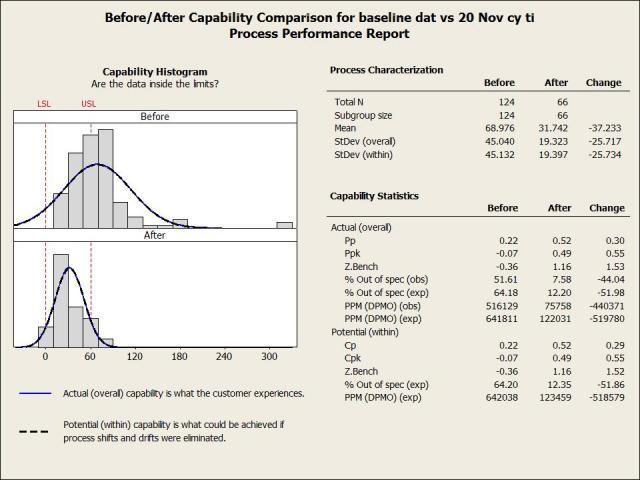

The team employed Minitab Control Charts to compare process stability before and after the new process was implemented, which helped the team confirm their solutions were meeting project goals.

Results

The comparison of before-and-after Control Charts revealed a dramatic change in the MMRB process cycle time—a decrease from an average of 61 days to 29 days from start to finish. This greatly surpassed the team’s goal of an average 45-day cycle time. The new MAR2 process also reduced error rates in process documentation, from 30% to less than 1%.

Another impressive operational improvement from this project included a decrease in Defects per Million Opportunities (DPMO), which dropped from 516,129 to 75,758. With the new process now standardized and centralized through one location, staff hours spent per MMRB case decreased from 5.5 hours to 3.5 hours, or by more than 74,800 hours annually. The improved process will save an estimated $15.3 million each year, for a total financial benefit of $99,805,881 between 2011 and 2017.

To read this entire case study or to read others, visit Minitab Case Studies.